AGV and AMR Safety Standards. You should comply with these ones

There is not any mandatory and specific safety standard for mobile robots agvs or amrs. But... it does not mean that you should not comply with the most relevant ones.

There is not any mandatory and specific safety standard for mobile robots agvs or amrs. But... it does not mean that you should not comply with the most relevant ones.

My name is Alfredo Pastor ... and I have a mission, let you know everything about mobile robots safety... let's try.

My name is Alfredo Pastor ... and I have a mission, let you know everything about mobile robots safety... let's try.

In this article I explain what are the main standards to be taken into consideration if you wish to produce, install or use safe mobile robots.

|

👨🏼🏫 This content is part of the learning material included in the online course: AGV & AMR Safety Course: From Design to Deployment Next opening: March 2024, write me at |

What are safety standards for automated vehicles?

AGV safety standard in Europe and International

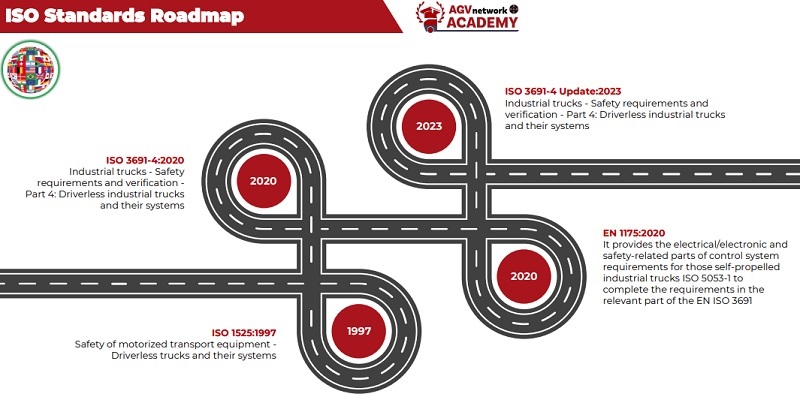

The only safety standard applicable in Europe and internationally is the EN ISO 3691-4:2023

✅ EN/ISO 3691:4-2023 - Industrial trucks — Safety requirements and verification — Part 4: Driverless industrial trucks and their systems

It specifies the safety requirements for driverless industrial trucks and their systems.

These trucks are defined as powered trucks designed to operate automatically, which can include a variety of vehicles such as "automated guided vehicles" (AGVs), "autonomous mobile robots" (AMRs), " "automated guided carts," "automated tuggers," and "under carts."

This standard is applicable to driverless industrial trucks that may have various operational modes, including automatic modes that require operator actions, the capability to transport riders, manual operation modes, and a maintenance mode for manual operation of truck functions.

It details safety protocols and requirements to ensure the safe operation of driverless industrial trucks, considering their autonomous nature.

AGV and AMR safety standard in the USA

The main agv and amr safety standards in the USA are the ANSI/RIA 15.08 part 1 and 2, the UL3100 and the ANSI/ITSDF B56.5-2019. Let's have an overview 👀

✅ ANSI/RIA 15.08 - Industrial Mobile Robots - Safety Requirements - Part 1: Requirements For The Industrial Mobile Robot

Specifies safety requirements for industrial mobile robots (IMRs). The document covers various aspects, including hazard identification and risk assessment, design requirements and risk reduction measures, verification and validation of risk reduction measures, and information for use and markings.

With the increasing use of mobile robots in industrial settings, there was a need for a specific standard addressing their safety, beyond the existing R15.06 for fixed industrial robots and B56.5 for Automatic Guided Vehicles (AGVs). The standard is designed for the manufacturers of industrial mobile robots, indicating how to design and manufacture a safe IMR.

Classification of IMRs:

-

- IMR Type A: Autonomous Mobile Robot with only an autonomous mobile platform, capable of moving and navigating through free space.

- IMR Type B: IMR Type A plus an attachment that is not a manipulator, which can be passive or active.

- IMR Type C: A mobile manipulator, combining an industrial robot arm (as defined in R15.06) with a mobile platform. This type comes in two varieties: one with an autonomous mobile platform and the other with an AGV as the mobile platform.

✅ ANSI/RIA 15.08 - Industrial Mobile Robots - Safety Requirements - Part 2: Requirements For The Industrial Mobile Robot Systems and Applications

The Part 2 provides safety requirements for deploying IMR systems into an industrial environment. R15.08-2 specifies requirements for integrating, configuring, and customizing an IMR or fleet of IMRs into a site.

The standard offers guidance on safe integration practices for these systems, addressing the need for common safety requirements and expectations for IMR systems and system integrations.

While Part 1 (ANSI/RIA R15.08-1-2020) established common safety requirements for IMR manufacturers, Part 2 is tailored for system integrators. It provides a common set of requirements for IMRs, allowing for flexibility to develop unique solutions.

The standard covers adaptations necessary for the application and the facility in which the IMRs will be used, including safety requirements when IMRs interact with workstations, charging stations, and other equipment. It also addresses safety considerations regarding the deployed operating environment.

Following the publication of Part 2, the R15.08 committee plans to develop R15.08 Part 3, which will provide safety requirements for users of IMR systems and applications. The committee will also consider developing technical reports to address emerging topics in mobile robot technology, including multi-sensor fusion, additional stability testing, stability validation, and dynamic stability testing.

✅ UL3100

Governs the safety of automated mobile platforms (AMPs), ensuring they are safe to use in different environments, including warehousing and manufacturing.

UL 3100 applies to mobile platforms used for lifting, carrying, product picking, towing, and similar activities, often facilitated by various attachments like grippers or suction mechanisms.

⚠ UL3100 is not applied to vehicles with forks!

The standard addresses essential safety risks in industrial environments, focusing on hazard and injury prevention, object detection and avoidance, risk assessment, functional safety, robotic payloads, and product integration.

It includes measures to reduce fire risks, such as containing fires within the product until they can be extinguished.

Additionally the UL 3100 emphasizes the safety of batteries and battery management systems (BMS) used in AMPs. It aims to mitigate thermal runaway risks, especially for lead-acid or lithium-based rechargeable batteries.

✅ ANSI/ITSDF B56.5-2019

The B56.5-2019 is primarily concerned with unmanned guided industrial vehicles and the automated functions of manned industrial vehicles. These vehicles typically include Automated Guided Vehicles (AGVs) that navigate predefined paths in industrial settings.

AGVs often come in various forms, including those equipped with forks for lifting and transporting materials. Therefore, the ANSI/ITSDF B56.5-2019 standard is likely to cover vehicles with fork attachments,

Other Important Autonomous Robots Safety Standards

The standards listed above lay the groundwork for ensuring comprehensive safety across all aspects of mobile robot operation.

Nevertheless, it's imperative to navigate a complex landscape of safety standards that spans various jurisdictions and sectors.from electrical safety to fire hazards, and from machinery directives to wireless equipment regulations.

We can't forget the ....🔐 There are many other standards to be taken into consideration but this content is only Available for Registered members . Join now and enjoy all the content. If you do not have an account yet, you can register here.

Conclusions and advice about the agv and amr safety standards

✅ First : 🙋🏼♂️ The specific AGV/AMR Safety standards are not obligatory

When embarking on the integration of mobile robots into your operations, it's crucial to understand that while standards like ISO 3691-4:2023 and ANSI R15.08 are not legally mandatory, they provide essential guidelines for ensuring safety. Reputable manufacturers and integrators of mobile robots will voluntarily adhere to these standards as a demonstration of their commitment to functional safety and industry best practices.

Select a supplier with a solid track record in functional safety and whose mobile platforms are in compliance with relevant safety standards. This not only assures quality but also ensures adherence to established safety protocols.

✅ Second: 👛 Buy and understand the standards

This article introduces the standards, but it is merely a starting point. To thoroughly grasp the potential risks and the appropriate mitigation strategies, it is advisable to obtain and study the full text of the relevant standards.

✅ Third: 👑 Risk Assessment is the King....🔐 Content Available only for Registered members . Join now and enjoy all the content. If you do not have an account yet, you can register here.

The final compliance is shared: suppliers must be diligent in providing thorough safety information, while users must be proactive in understanding and implementing these standards.

Therefore, establishing a robust dialogue to ensure all safety aspects are thoroughly addressed is not just beneficial but essential for a seamless and safe integration of mobile robots into the workplace.

|

Related articles AGV Sensors : 101: A Beginner's Guide to the Most Important Components AGV Safety: A comprehesive guide to understand automated guided safety |

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.