Amazing Automated Guided Vehicles: In-Depth GUIDE

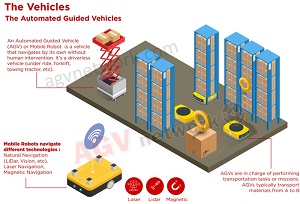

Automated guided vehicles (AGVs) are PLC or PC controlled self-driving robots that follow predetermined paths depending on different agv navigation technologies like magnetic guidance, laser guided vehicles, etc.

Automated guided vehicles (AGVs) are PLC or PC controlled self-driving robots that follow predetermined paths depending on different agv navigation technologies like magnetic guidance, laser guided vehicles, etc.

Moreover, AGVs count on sensors that automatically stop the vehicle avoiding running into obstacles (for example, people).

In this article, I answer to this question: What are the automated guided vehicles? and I explain topics like how do they navigate, how much do they cost, where are they used, the types of robots, etc.

My name is Alfredo Pastor... I've sold and installed hundreds of agvs from different suppliers. I simply love the way they improve productivity and safety.

My name is Alfredo Pastor... I've sold and installed hundreds of agvs from different suppliers. I simply love the way they improve productivity and safety.

If you have a particular interest in a topic, you will find different links leading to specific articles and whitepapers that go into great detail about that subject.

Wait a moment! you can download my free ebook too. Available only for cool registered members 😎.

What does AGV stands for? What is AGV Meaning?

AGV is the acronym of AUTOMATED GUIDED VEHICLE. Yes, I have started from the very beginning. 🤓

What is an Automated Guided Vehicle AGV?

Automatic guided vehicles (AGVs), also known as self-guided vehicles or driverless robots, are material handling systems or load carriers that navigate automatically across a warehouse, distribution center, or manufacturing plant without the assistance of an onboard operator or driver.

This video by Kollmorgen helps to understand better what an agv is.

I am confident that you have also heard about Autonomous mobile robots or AMR. Well, Automated guided vehicles behave and maneuver differently from autonomous mobile robots (amr).

AMRs, in essence, do not follow a predefined path and can avoid obstacles rather than just halting and waiting for the obstacle to be removed.

I'm not going into detail about the AMRs here, there are many other articles in this web. I recommend checking out this insightful article for an in-depth understanding of the difference between AGV and AMR.

Curious to see more AGVs in action? Check these vehicles out.

AGV bots can be used everywhere. There are many AGV applications where automated guided vehicle performance are simply awesome. For example, warehouse AGVs handle tasks like storage and retrieval, significantly enhancing picking processes in warehousing and distribution.

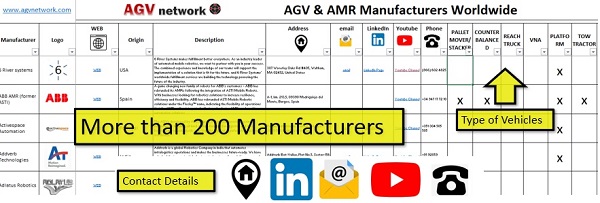

The agv market is rapidly growing, with an increasing number of automated guided vehicle manufacturers offering innovative solutions. For those seeking an AGV supplier, i have prepared a comprehensive list of over 200 providers, serving as an excellent starting point for your search.

This is an extract of the list...

| Click here to download the manufacturer list |

Great! Now, you know what an agv vehicle is. Let's go deeper . The following chapters dive into the main topics related to the automated guided vehicles.

|

Table of Contents: What are the main parts of an Automatic Guided Vehicle? AGV 101 - Some pills of knownledge |

What is an AGV System (AGVS)?

An Automated Guided Vehicle System instead , is a set of automated elements united by a superior management system. These elements are basic and they interact in order to make the system work.

In other words, it is not only about the vehicles, put togheter:

✅ The Pc/plc controlled vehicles

✅ An outstanding navigation and vehicle management intelligence

✅ A top in class automated safety system

✅ A great AGV System Management Software for mission management, fleet coordination, and

... and you will have an automated guided vehicle system.

What is an agv system made of?

The main elements of an AGV Robot System are the AGV Vehicles, the AGV Management System and the Peripherals.

1️⃣ The AGV vehicles, which carry out the jobs or missions physically. In this section I will explain:

The different types of agv robots

What are the main parts of an AGV?

2️⃣ The AGV Management System (so the brain) that controls the AGV system, managing orders, traffic, etc.

3️⃣Some Peripherals needed to make the system work (charging stations, communication devices, etc)

Check this video by Kollmorgen to have quick overview about the different components of an AGV System.

There are large AGVs that can lift materials up to 12 m/40 ft on racks, as well as compact, quick, and nimble AGVs that can move carts or shelves all throughout a plant.

Some types of automated guided vehicles Automated Guided Cart or Under Ride ![]()

The smallest type of AGV suitable for cart transportation or totes handling in ecommerce applications. Automated Pallet Jack ![]()

Best in class for moving pallets autonomously from floor to floor or max 1,5 m height. Automated Forklift ![]()

The Automated King. Everything could be moved by an automated forklift. The only limit is your imagination. Automated Reach Truck ![]()

The solution for stocking materials in high racks and moving around the factory.

Very Narrow Aisle AGV ![]()

The "aisle master". The best vehicle to deposit pallets at 12 m height with minimum aisle of 1,7 m width. AGV Tow Tractor ![]()

High capacity transportation, able to tow several trolleys in one shot. Unit Load AGV ![]()

Fast and conveniente. The best alternative to traditional fix, old fashion conveyors. UV Robot ![]()

The virus killer. A combination of state of the art navigation and disinfecting UV capacity. A must in the "new normal".

|

Want to learm further about the different types of AGVs? More agvnetwork's articles: |

What are the main parts of an Automatic Guided Vehicle?

An AGV is mainly composed by 5 elements: Navigation System, Safety System, Power System, Motion System and Vehicle Controller.

✅ AGV Navigation System in charge of acquiring the info needed to drive and follow a given track or direction. There are several types of navigation: laser, natural, magnetic, etc. Keep on reading, I explain them in the next points.

✅ The AGV Safety System that ensures that all the movements and manoeuvres are performed in safe conditions. The concept is easy to understand. The robot must stop before running into something or someone. The main parts are the safety laser scanners and the safety plc.

|

Related Articles: The AGV Safety System: In this article you will learn the main safety AGV standards, types of sensors and the key concepts to consider while installing an agv project. |

✅ Power System that provides the energy needed for the vehicle movement and accessory functions. The main elements are the agv battery and the charging solution.

|

Related Articles: The AGV Battery : What are the main types of batteries used for the AGV? How much do they cost? Pros and cons? AGV battery charging systems : How do AGVS charge? Opportunity charging, online charging, battery swap. Benefits and drawbacks. |

✅ The Motion System in charge of converting the power into motion. Here we find the motors, motor-wheels, drivers, etc.

✅ The Vehicle Controller that is the brain of the AGV. It gathers and coordinates all the info received from the other systems, thus, navigation, safety, motion, etc.

The AGV Management System - AGV Traffic Control and AGV Control System

An AGV Management System is a sophisticated suite of software solutions designed to manage and coordinate the operations of a fleet of mobile robots within an industrial or logistical environment.

Here comes the brain!!!

These systems are integral to modern material handling and intra-logistics operations, offering a range of functionalities to ensure efficient, safe, and optimized utilization of self-driving robots. The Management System can be installed on various platforms, from PC servers to cloud servers.

What are the key components of an AGV Management Software?

- Host Computer/Server: The central processing unit that orchestrates the entire system.

- Graphical User Interface (GUI): This interface provides a visual representation of the mobile robot’s operations, allowing for real-time tracking and management.

- Communication Systems: These systems, utilizing technologies such as wifi or wired connections, facilitate effective communication within the mobile robot network.

What are the main tasks of the AGV Management Software?

This software performs a myriad of crucial tasks:

- Administration of transportation orders.

- Mission management.

- Optimization of transportation schedules.

- Traffic control of self-driving vehicles.

- Integration with other management software, like ERP and WMS.

- Integration and Compatibility.

These systems are designed for seamless integration with customer systems using various standards, including APIs, SQL, web services, FTP, message queues (MQ), and TCP/IP sockets. This level of compatibility is vital for integrating the mobile robot system with existing infrastructure.

AGV Sytem Peripherals

The rest of the world interacting with the AGV System… peripherals can be

-

Screens, monitors, buttons, etc, for interface with operators. These peripherals could also generate missions, for example a “CALL AGV Button” in a working station of an Assembly Line.

-

PLCs or other automation devices needed for communicating with robots, doors, conveyors, etc. Commonly, they are OPC or I/O machines to exchange info with these external elements. What you need to know is that, for example, if AGV has to open a sliding door, it will be necessary to install a device to communicate with the door.

Automated Guided Vehicles 101 - Some pills of knownledge

Let's make a recap of the main topics related to the AGVs. Here below you will find some useful information about the AGV technology and their market. If you wish to know further, just follow the different links redirecting to specific articles that explain each topic into detail.

How do AGVs navigate?

Automatic guided vehicles navigate thanks to different AGV Navigation systems as well as sensor-based guiding systems control their movement. The Navigation Technology defines how does the agv localize, drive and follows a path.

Summing up, these are the most important navigation technologies:

✅ AGV Magnetic Navigation (magnetic tape, spots). So the AGV follows its path made by a magnetic tape or by magnetic spots on the floor.

✅ Laser Navigation gives the famous LGV (Laser Guided Vehicle). In this case, AGVs count on a Laser Navigation that sources laser beams that impact on reflectors positioned on the working emvironment. Laser is sent back to the Laser Navigation and the AGV is able to calculate its position and trajectory.

✅ Free navigation systems. These systems do not need any kind of hardware to be installed in the working area. They track the environment through different technologies (Contour-based, SLAM, LiDAR, Vision, etc) and define their position and path thanks to the info received from the surrounding environment. Mobile Robots with Free or Natural Navigation are known as Autonomou Mobile Robots (AMR:

|

Want to learm further about the different agv navigation methods? More agvnetwork's articles: |

Easy to install. No invasive installation. Accurate positioning. High speed No costs due installation maintenance Modifications require supplier intervention AGVs with this technology are expensive Easy to install. Easy to modify No invasive installation Accurate positioning. Reliable navigation AGVs with this technology are less expensive Magnetic tape maintenance. Magnetic tape cost Not suitable for complex paths Easy to install Flexibility: Easy to add new paths or modify existing ones Low cost of installation No invasive installation. No costs due to implementation maintenance Lower reliability in chaotic and variable environments Highly effective and efficient free navigation is still very expensive. Lower positioning accuracy compared with other navigation methods Free environment Accurate positioning. No costs due to implementation maintenance Installation is easy but it still is more complex than magnetic tape Magnetic tape installation is faster and easier to modifyNavigation Tech Advantages Disadvantages

AGV Battery System

As any other electrical vehicle, AGVs need power that is provided by the batteries. 🔋 The importance of battery types and their management in AGVs is often underestimated, yet it is critical to overall system performance.

Choosing the right battery and implementing an effective charging strategy are key factors that significantly influence the efficiency, operational continuity, and maintenance costs of AGV systems. Proper battery management ensures optimal performance and longevity, directly impacting the success and reliability of AGV operations.

Charging strategies for these batteries include manual swapping, automatic battery exchange, and opportunity charging, where AGVs are charged during short breaks in their operation. Each strategy balances factors like operational efficiency, downtime, and battery lifespan.

- What kind of battery is the best? Gel, Open Pb-Acid, Lithium...

- How do we manage battery recharging strategy in order to maximize the AGV performance?

Below, you'll discover two dedicated articles on these subjects, where I delve into the technical and economic aspects that need to be comprehended.

AGV Types of Battery and AGV Charging Systems

AGV Cost?

The total cost of an AGV system is a combination of several elements.

🤷🏼♂️ Apologize, but I can't describe here all the costs related to an agv system, but you can visit this article: How much do AGVs cost? where I provide specific and real values.

Even more!! If you wish all the info about costs in a nice "pack", DOWNLOAD my whitepaper.

The AGV system cost topic is widely covered in our free whitepaper with nice pictures and infographics.

| Click here to download the whitepaper |

Are AGVs safe?

Are AGVs safe? Absolutely Yes, they are safer than manned vehicles. AGVs don’t impact anything. AGVs are provided with safety sensors that prevent them from running into people or things.

What are the AGV Safety Rules?

There are several standards that should be taken in to consideration. The most relevant are:

- The ANSI/ITSDF B56.5-2019, the UL3100 , the ANSI/RIA 15.08 part 1 and part 2 in US.

- In EU there is the EN ISO 3691-4:2023 “Industrial trucks — Safety requirements and verification Part 4: Driverless industrial trucks and their systems”.

These standards provide the main rules that mobile robots should comply with.

What are the main AGV Safety Elements and Devices?

- Safety Laser scanner and/or collision avoidance system

- Pressure-sensitive bumpers

- Safety PLC

- Emergency stop devices

- Warning lights

- Audible warning/alarm signals

- Awareness signs on AGV Vehicle

| Click here to download the whitepaper |

AGVs pros and cons

AGVs are becoming an essential key in manufacturing facilities and warehouses. AGV bots offer many advantages such cost reduction, improved safety, etc. In this article, I have identified and explained 11 advantages of AGVs, for example:

- AGVs are safer than human manned vehicles. Lots of sensors and rules avoid the AGV impacting anything.

- Improved Ergonomics. AGVs can perform heavy harmful tasks such towing trolleys or can work in cold areas.

- Infection Risk reduction. AGVs do not transmit viruses.

- Indirect Cost Reduction. Less training, water, light, parking cost, etc.

- and many others....

But, there are some disadvantages of AGVs to be understood before installing an AGV system

- WiFi reliability dependence

- It could be difficult ot have two different suppliers in the same floor

- AGVs are less flexible than manned vehicles

- Initial capital cost is... not cheap

- AGVs can't work in all the environments

Automated Guided Vehicles Applications - What are AGVs used for?

AGVs can be used in a wide variety of applications to transport many different types of materials including pallets, rolls, racks, carts, and containers.

AGVs (togheter with AMRs) are one of the most efficient tools used for warehouse automation.

Basically, we can find mobile robots everywhere. In the following lines I summarize some these utilizations and tasks.

What are the main taks for AGVs?

Raw material handling

AGVs are commonly used to transport raw materials such as paper, steel, rubber, metal, and plastic. This includes transporting materials from receiving to the warehouse, and delivering materials directly to the production lines.

Work-in-progress movement

Work-in-process movement is a very common AGV application and includes the repetitive movement of materials throughout the manufacturing process.

Pallet handling

Pallet handling is an extremely popular application for AGVs as repetitive movement of pallets is very common in manufacturing and distribution facilities.

Finished product handling

Moving finished goods from manufacturing to storage or shipping is the final movement of materials before they are delivered to customers. These movements often require the gentlest material handling because the products are complete and subject to damage from rough handling.

Hazardous Materials Handling

Some material handling are better left to an AGV. The material or product to be carried may be dangerous or the actual operating environment in which the AGV is operating may be harmful (e.g. radioactive, chemicals etc) to an human operator

What are the industries using AGVs?

AGV can be used everywhere.

Automotive

Automated guided vehicle systems (AGVS) for the automotive industry and its suppliers. For transporting engines, tools, vehicle and chassis components.

Food & Beverage

In the food and beverage industry, automated guided vehicle systems (AGVS) transport raw materials and finished products. Available in stainless steel and with splash water protection, with barcode and RFID scanners, and metering or weighing functions.

Packaging

In the packaging industry and printing plants, automated guided vehicles (AGV) move pallets with carton materials and print products.

Production

Automated guided vehicle systems (AGVS) transport raw materials and finished parts in the steel and plastics industries. Integration of materials handling system and high-rack storage systems, ERP systems, and warehouse management.

Pharma

Automated guided vehicle systems (AGVS) for the pharmaceutical industry, biotechnology, and life sciences. For clean rooms, controlled material flow, and validation. GMP and FDA compliant.

Healthcare and Hospitals

In particular main AGV tasks in hospitals regard transportation of:

- Meals from kitchen to wards and return of empty trays to kitchen.

- Waste bins and trolleys. Full and empties management.

- Linen transportation (clean and soiled).

- Deliver trolleys/carts for cleaning and activate cart-washing systems

- Sterile Supplies Transprotation

- Drugs and other supplies in the Hospital (wards, theatres, pharmacy, laboratories etc)

As you can see... there are many nice applications where autonomous robots can make the difference.

|

Related articles

|

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.