14 Types of Autonomous Mobile Robots (AMR) with examples

AMRs are thata big thing changing the way we produce and stock material. More intelligent and user-friendly systems are opening the doors to a wide range of applications of autonomous robots. Let's discover all the varieties of AMRs!

AMRs are thata big thing changing the way we produce and stock material. More intelligent and user-friendly systems are opening the doors to a wide range of applications of autonomous robots. Let's discover all the varieties of AMRs!

These AMRs are reshaping manufacturing and warehousing

The technological advancements in robotics are ushering in new horizons within the industrial sector, especially in factories and warehouses.

Leading this transformative charge is the Autonomous Mobile Robot (AMR), an intelligent machine designed for versatility, easily adapting to different tasks depending on its configuration and attachments.

In fact, AMR Warehouse have become the Kings Of Warehouse 👑...

An autonomous mobile robot is a driverless robot that navigates autonomously and is able to decide its route, being possible to avoid obstacles.

If you want to know more about amrs (navigation, safety, applications, etc) do not miss this article: What is an Autonomous Mobile Robot?

What are the types of autonomous mobile robots?

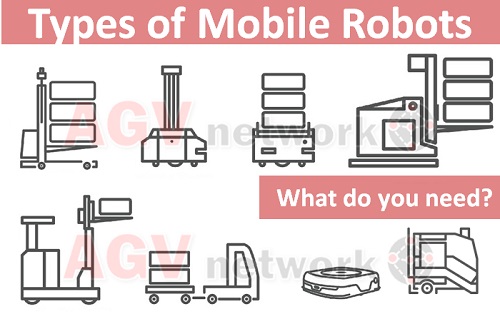

Broadly speaking, AMRs fall into three categories depending on their application:

✅ Transport Inventory AMRs : These robots automate the transfer of items (boxes, pallets, containers, carts, etc) within a facility. AMRs today handle both large loads and individual items efficiently.

✅ Picking Assist AMRs: Order picking is a significant part of operations due to its time intensity. There are two ways to improve picking. AMRs reduce travel time by bringing products to pickers or by picking products from shelves or totes.

✅ Sortation AMRs: These robots make sorting easier with different tools. They quickly sort packages, online orders, and returns, moving items smoothly.

In essence, AMRs transform and optimize operations by automating time-consuming tasks, offering adaptability to varying business needs.

In the following lines, I will provide an in-depth look into the different kinds and examples of AMRs and how they're used in different material handling processes.

Platform AMRs

Let's start from the very beginning.

This is the most basic AMR Robot type while it is the base for many versatile applications depending on the attachments or devices installed on it.

They are just that... a platform with several mounting options, allowing for custom applications based on user needs.

✅ Benefits

Their adaptability means businesses can craft tailored robotic solutions as per specific requirements.

✅ Use-cases

They're indispensable in projects demanding specific robotic interventions or when adapting to dynamically changing operational demands.

Manual Loading AMRs

Manual Loading AMRs come with shelves, bins, or custom attachments. Workers can manually load and unload inventory, making them ideal for tasks that require flexibility in item handling.

✅ Benefits

These AMRs allow flexibility for workers to manually handle inventory, making them perfect for transporting diverse items without a set pattern.

✅ Use-cases

They're the perfect solution for ZONE PICKING. They're particularly useful for moving products from assembly lines to storage areas and for distributing tools and parts within a manufacturing environment.

Rack and Cart Lifting AMRs

Designed to go beneath a rack or cart, they lift it using a plate mounted on the AMR. It’s an efficient solution for transporting larger volumes in one go.

✅ Benefits

They efficiently transport larger volumes, thereby reducing the number of trips required.

✅ Use-cases

Commonly found replenishing stock in retail settings or moving materials between distinct production zones.

AMR platforms for pallet lifting

These are heavy-duty robots capable of transporting pallets between various points in a warehouse or production facility.

They drive beneath pallets, lifting them for transportation, requiring the pallets to be on a suitable support for access.

✅ Benefits

Facilitates the easy movement of bulk items or products, enhancing workplace safety by minimizing manual pallet movement.

✅ Use-cases

Primarily found in warehouse loading and unloading zones and in transporting goods from storage to dispatch areas.

AMRs for Dollies Lifting

With a single lifting jack, these AMRs can lift and move equipment like wheeled dollies loaded with goods, automating dolly transport processes.

✅ Benefits

Simplifies dolly transportation processes by eliminating manual intervention.

✅ Use-cases

These are ideal for moving goods in distribution centers or facilitating luggage transport in airports.

Cart Pulling AMRs

These robots go underneath a cart, attaching themselves using pins. Compared to Tugger AMRs, they are more flexible and require smaller footprint but require carts designed to accommodate them. Moreover, tuggers use to have more payload capacity.

✅ Benefits

They require lesser space and showcase better maneuverability compared to Tugger AMRs.

✅ Use-cases

Especially valuable in transporting goods in narrow corridors or crowded settings.

Conveyor AMRs

Integrating with conveyor systems, these AMR platforms come with conveyor attachments for tasks like automated case picking and transfers.

✅ Benefits

Facilitates seamless material transfer, augmenting the efficiency of automated case picking processes.

✅ Use-cases

Often employed in transferring items between different conveyor belts or lines.

Mobile Picking Robots

Equipped with robotic picking mechanisms, they can transport items like totes and bins from shelves for fulfillment.

✅ Benefits

Offers enhanced accuracy and speed in item retrieval, optimizing fulfillment processes.

✅ Use-cases

Predominantly seen in e-commerce fulfillment hubs or specialized sorting facilities.

💡 Wish to know further? Do not forget to read this article : What are Order Picking Robots?

Mobile Cobots with Manipulators

A fusion of AMR movement with robotic arms, they're suited for advanced automation tasks like flexible picking, packing, and palletizing.

✅ Benefits

They bring unparalleled flexibility to processes such as picking, packing, and palletizing.

✅ Use-cases

Their versatility makes them ideal for assembling products in factories or sorting tasks in postal centers.

💡 More info? Advantages of Mobile Cobots

Heavy Load and Large Custom AMRs

Designed for extreme loads, these heavy-duty AMRs can transport items weighing thousands of kilograms, such as metal coils and reels.

✅ Benefits

These AMRs allow flexibility for workers to manually handle inventory, making them perfect for transporting diverse items without a set pattern.

✅ Use-cases

They're particularly useful for moving products from assembly lines to storage areas and for distributing tools and parts within a manufacturing environment.

Sortation AMRs

These AMRs streamline the sorting process with various handling technologies. They manage tasks like high-speed parcel sortation, ecommerce order fulfillment, and returns handling.

✅ Benefits

These AMRrobots work fast and accurately, allowing for tight sorting areas and taking up less space.

✅ Use-cases

They're used in postal services and ecommerce.

Pallet Jack AMRs

AMRs are not only platforms with different attachments and devices.

Pallet jack AMRs are nimble vehicles, easy to install and do not require any specific structure on the floor. They can simply pick/drop pallets from/to the floor or at max 1 m height (for example on conveyors)

Combining the benefits of AMRs and forklifts, these robots can lift pallets directly from the floor and deliver them to storage systems, even at height.

✅ Benefits

Provides automated pallet lifting and transportation, elevating safety standards and operational efficiency.

✅ Use-cases

Essential for replenishing stock on high shelves and transferring items across warehouse sections.

Forklift AMRs

Nowadays, thanks to the latest navigation and localization techniques, AMRs can substitute all kinds of forklifts (stackers, reach trucks, etc).

More and more traditional Forklift AGV manufacturers are implementing autonomous navigation into their vehicles, leading, in fact, to have proper Autonomous Forklifts.

Combining the benefits of AMRs and forklifts, these robots can lift pallets directly from the floor and deliver them to storage systems, even at challenging heights.

✅ Benefits

Provides automated pallet lifting and transportation, elevating safety standards and operational efficiency.

✅ Use-cases

Essential for replenishing stock on high shelves and transferring items across warehouse sections.

Tugger Autonomous Mobile Robots

Designed to pull carts like a convoy, these tow tractor robots can either automatically or manually latch onto a cart, making them excellent for transporting various wheeled containers or dollies.

✅ Benefits

Enhances transportation capacity by enabling the movement of multiple carts.

✅ Use-cases

Found in large manufacturing units, postal services or in hospitals for tasks like laundry or waste movement.

Conclusions

Autonomous mobile robots are defined not by their shape or size but by their ability to navigate and determine their own routes.

It's all about the intelligence inside, not the chassis outside.

As technology becomes more user-friendly, efficient, and affordable, the possibilities for different types of autonomous vehicles expand.

It's an exciting era where the design of a robot is limited only by imagination and practical needs.

|

Related articles...to learn more about agvs

Difference between AGV and AMR - What's the best solution?

Autonomous Forklift Companies - The Top Ten

Autonomous Mobile Robot Market- Trend and Growth

AMR Robot Applications- 7 applications that AGVs could not do |

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.